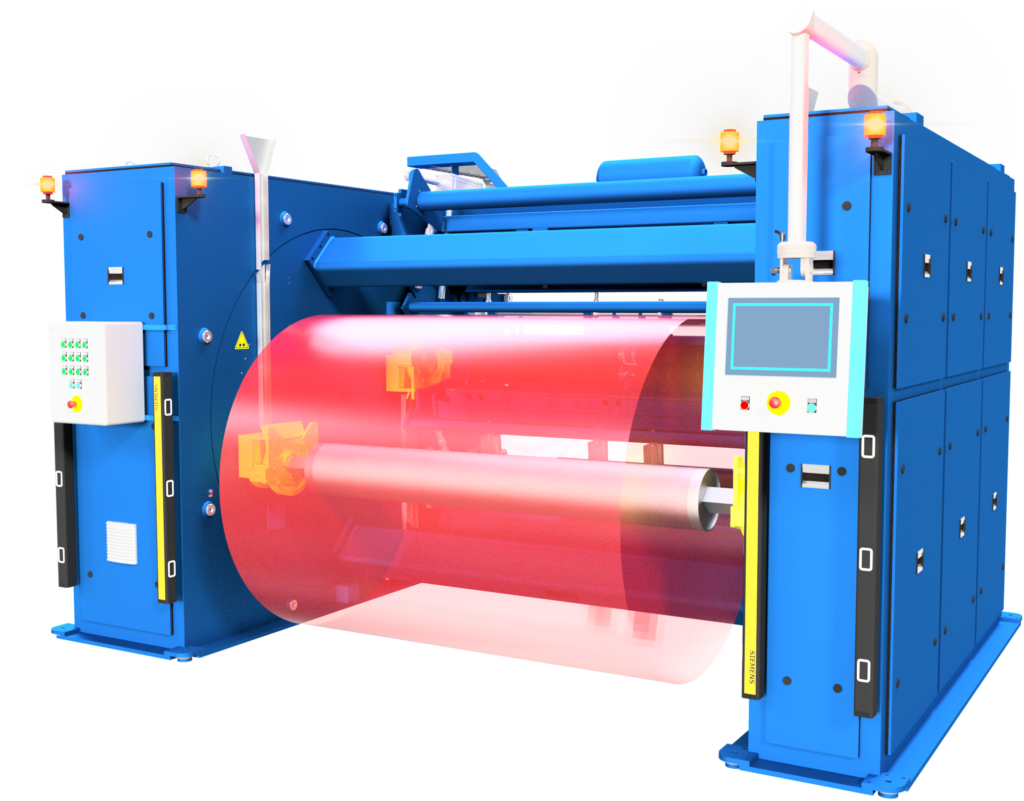

Rewinders

to rewind straight-edged and wrinkle-free jumbos of coated, dried or cured abrasive web

PS-rewinders are exclusively designed for the use in the coated abrasives industry.

Please let us know the definition of your requirements. We are pleased to quote you the right solution.

PS manufactures stationary single rewinders, mobile rewinders and fully automatic rewinders for a continuous non-stop production.

From manual cross cutting and manual joining of web, to fully automated cutting and change of jumbo, fully automated jumbo removal, automatic taping of web tail and fully automated inserting of new cores, from single rewinders or double rewinders for short changing times, we build our machines according to your demands.

All rewinders can be built as hot rewinders for temperatures up to 130° C. Heating of the rewinder housing with hot air, additionally IR-heating possible.

Our product range

- single rewinders

- mobile rewinders

- double rewinders for non-stop-production

- web accumulators

- automatic cross cutting units

- automatic taper

- automatic jumbo take out

- automatic feeding units for empty cores

- automatic joining of web ends to the empty core

- rewinders for hot rewinding

- IR-heating units

- web humidification units

- up to 2100 mm working width

- up to 1600 mm diameter

- up to 4000 kg jumboweight

- up to 150 m/min. winding speed

- wound grain side in or out

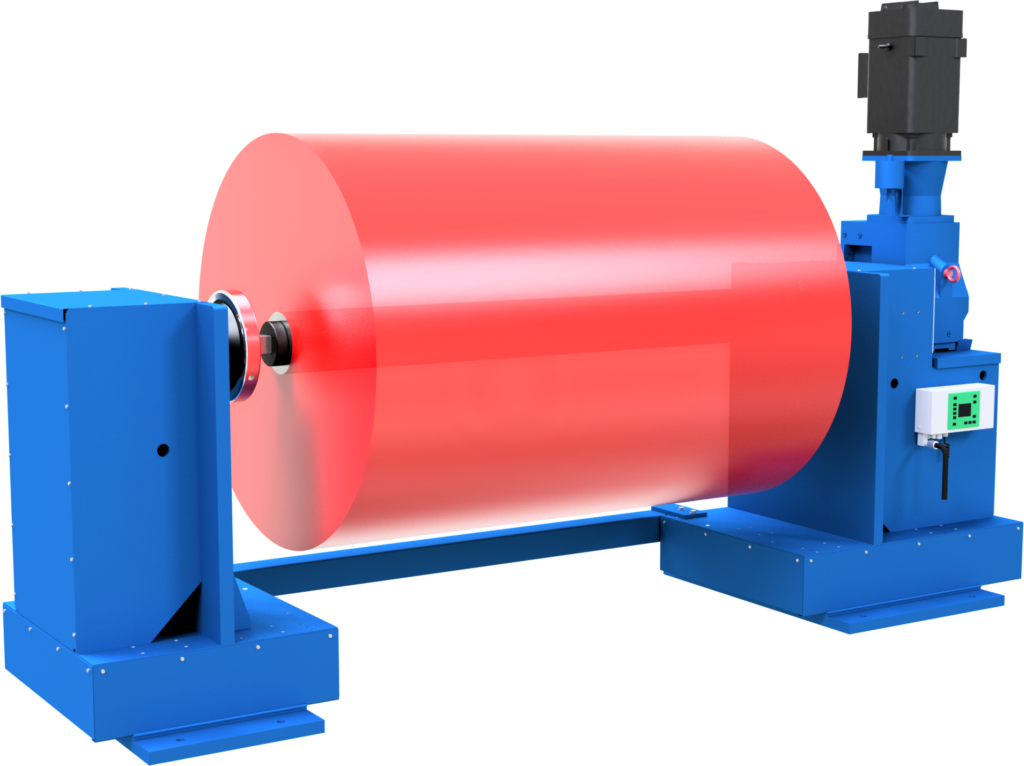

Rewinder – manually operated

Standard

- with square shaft for jumbo take-up

- with torque control

- with length measuring with measuring wheel

Additional features

- with shaftless jumbo take-up

- with winding chucks for cardboard cores of 6“

- with winding chucks for aluminum and steel cores

- with pneumatic or motor-driven adjustment of winding chucks

- with automatic web guiding

- with contact free length measuring

- with automatic cross cutting unit

- with load roll

- with automatic taper

- with automatic jumbo take out

- with automatic core feeding unit

- with automatic joining units for joining the web tails to steel or cardboard cores

- with winding calculator

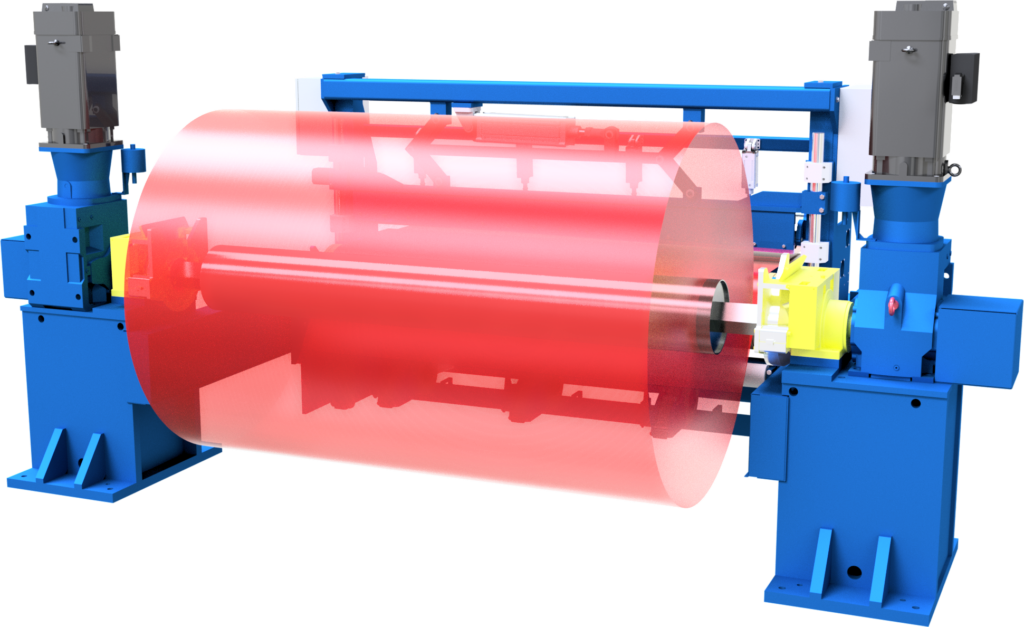

Rewinder – automatically operated

for fully automatic change of jumbo with winding, cross cutting, taping of web ends to the jumbo, take-out of jumbo, feed of new core, joining of web end to the new core and restart of winding

Standard

- with square shaft for jumbo take-up

- with torque control

- with length measuring with measuring wheel

- with automatic cross cutting unit

- with load roll

- with automatic joining units for joining the web tails to steel or cardboard cores

- with winding calculator

- with calculator for rest length of web

Additional features

- with shaftless jumbo take-up

- with winding chucks for cardboard cores of 6“

- with winding chucks for aluminum and steel cores

- with pneumatic or motor-driven adjustment of winding chucks

- with automatic web guiding

- with contact free length measuring

- with automatic taper

- with automatic jumbo take out

- with automatic core feeding unit

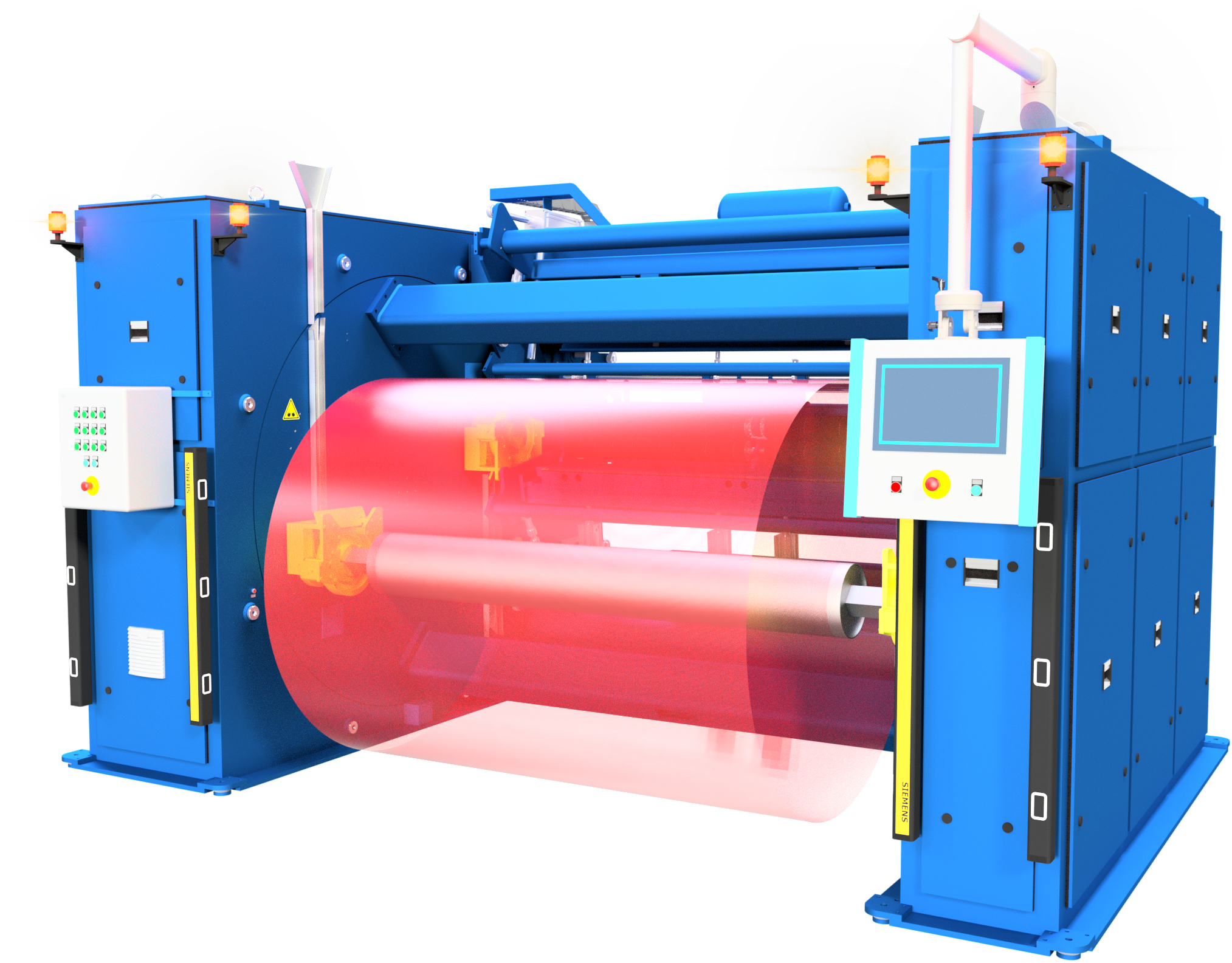

Turret rewinder – automatically operated

for fully automatic change of jumbo with winding, cross cutting, taping of web ends to the jumbo, take-out of jumbo, feed of new core, joining of web end to the new core and restart of winding

Standard

- with square shaft for jumbo take-up

- with torque control

- with length measuring with measuring wheel

- with automatic cross cutting unit

- with load roll

- with automatic joining units for joining the web tails to steel or cardboard cores

- with winding calculator

- with calculator for rest length of web

Additional features

- with automatic web guiding

- with contact free length measuring

- with automatic taper

- with automatic jumbo take out

- with automatic core feeding unit