Flexing Machines

for flexing of coated and cured abrasive web

PS-flexing machines are exclusively designed for the use in the coated abrasives industry.

Please let us know the definition of your requirements. We are pleased to quote you the right solution.

Our product range

Our delivery program PS-flexing machines comprises flexing machines in line and flexing machines in U-form

- up to 2100 mm working width

- up to 1600 mm diameter

- up to 4000 kg total weight

- up to 120 m/min. winding speed

- for wound grain side in or out

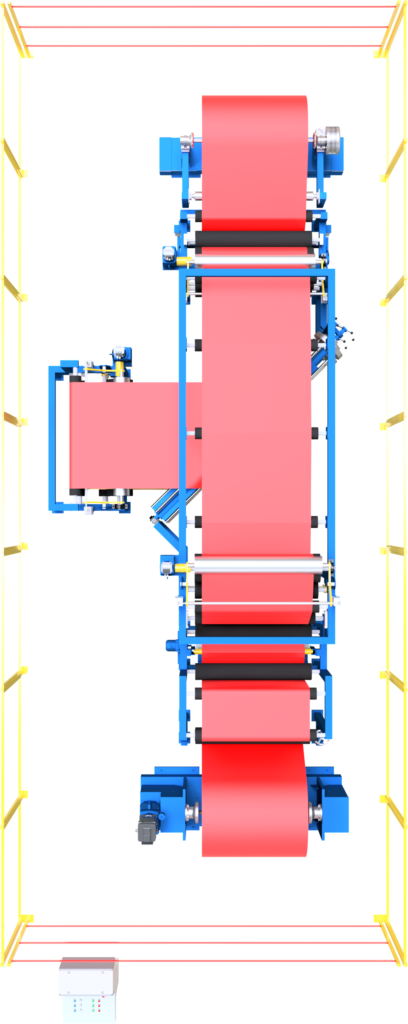

Flexing Machine inline

Standard

- with unwinder

- with 90°-rollerflex

- with 3 pulling units

- with 2×45° flexing stations

- with 90° knifeflex

- with rewinder

- with 5 servo-drives

- with square shaft for jumbo take-up

- with torque control

- with length measuring by measuring wheel

- with automatic web guiding

Additional features

- with shaftless jumbo take-up

- with winding chucks for cardboard cores of 3“ and 6“

- with winding chucks for aluminum and steel cores

- with pneumatic or motor-driven adjustment of winding chucks

- with cooling tunnel for web temperature reduction

- with humidification units

- with contact free length measuring

- with automatic cross cutting unit

- with load roll for the web

- with automatic taper for web tails

- with automatic jumbo take out

- with automatic core feeding unit

- with automatic joining units for joining the web tails to steel or cardboard cores

- with winding calculator

- with calculator for rest length of web

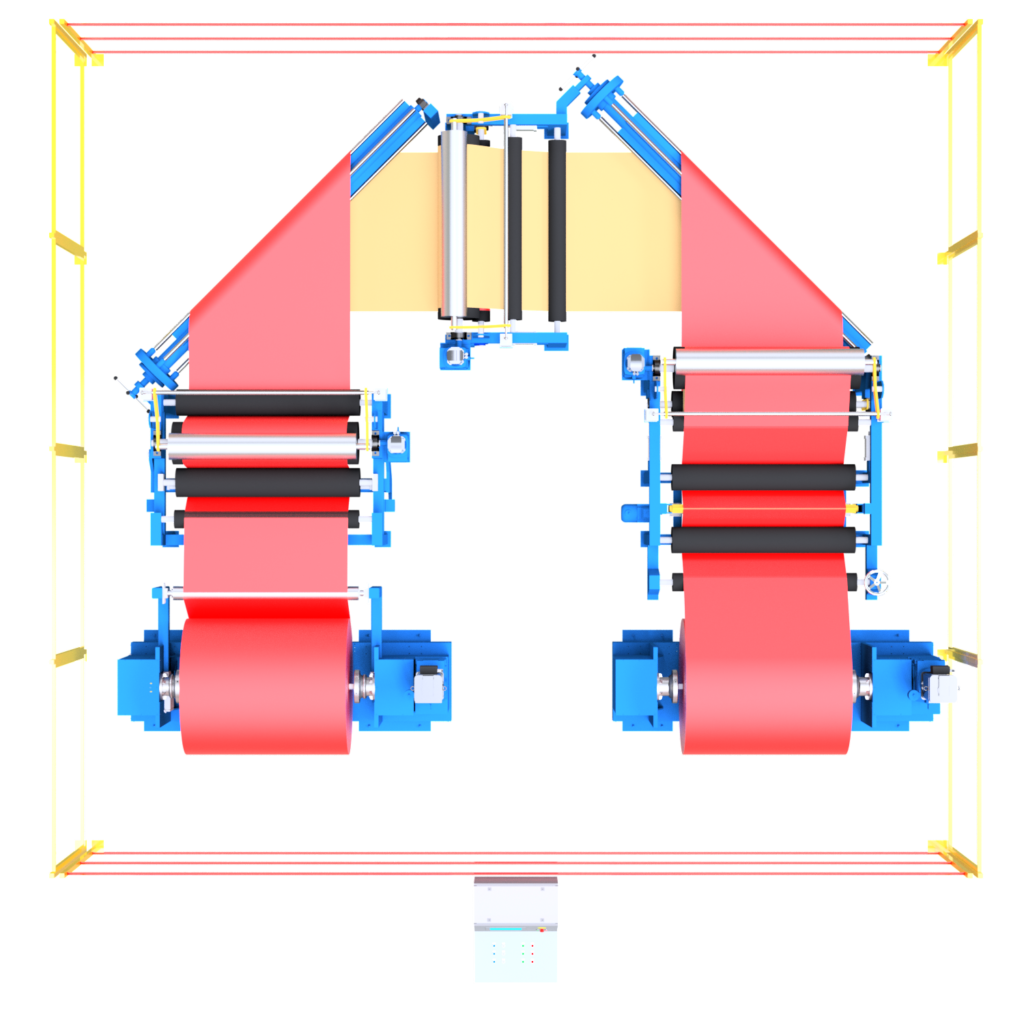

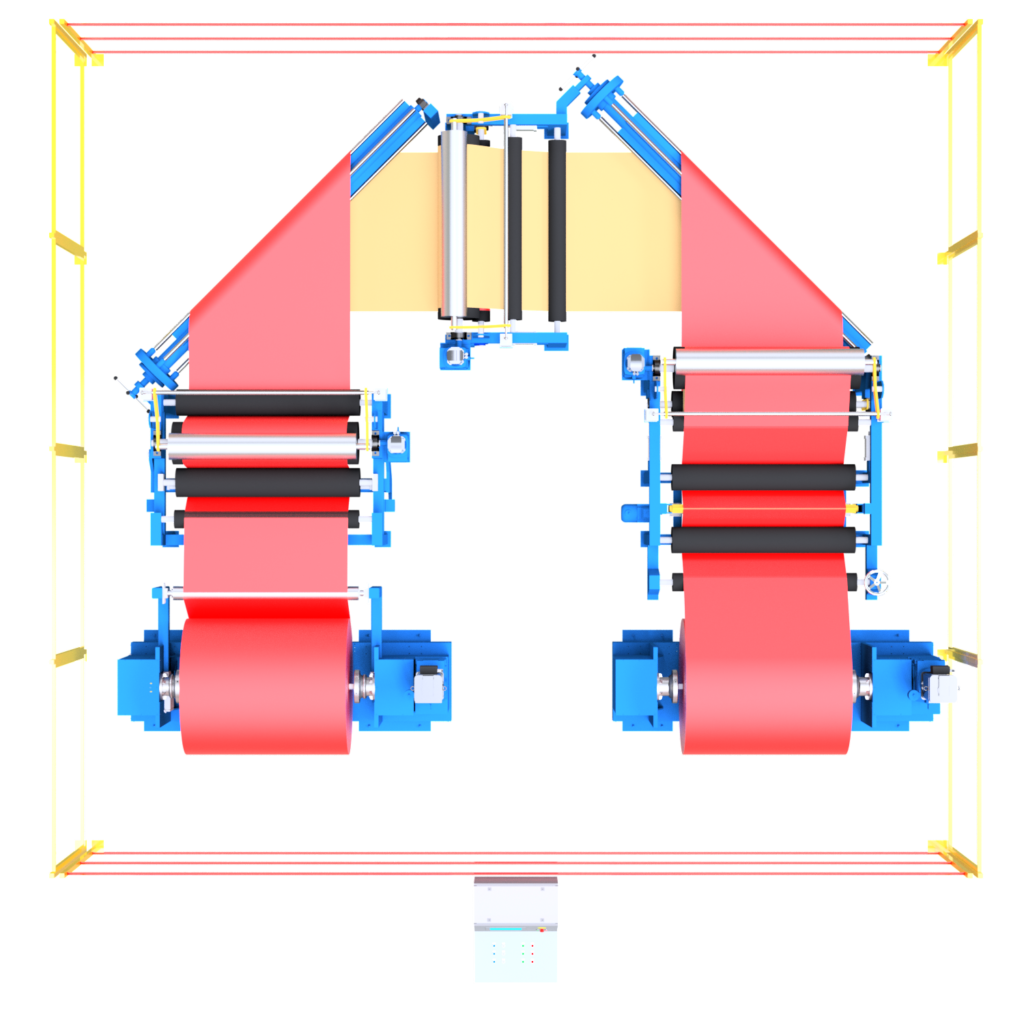

Flexing Machine in U-Form

Standard

- with unwinder

- with 90°-rollerflex

- with 3 pulling units

- with 2×45° flexing stations

- with 90° knifeflex

- with rewinder

- with 5 Servo-drives

- with square shaft for jumbo take-up

- with torque control

- with length measuring by measuring wheel

- with automatic web guiding

Additional features

- with shaftless jumbo take-up

- with winding chucks for cardboard cores of 3“ and 6“

- with winding chucks for aluminum and steel cores

- with pneumatic or motor-driven adjustment of winding chucks

- with cooling tunnel for web temperature reduction

- with humidification units

- with contact free length measuring

- with automatic cross cutting unit

- with load roll for the web

- with automatic taper for web tails

- with automatic jumbo take out

- with automatic core feeding unit

- with automatic joining units for joining the web tails to steel or cardboard cores

- with winding calculator

- with calculator for rest length of web